Shape it up!

Friday, April 30, 2021

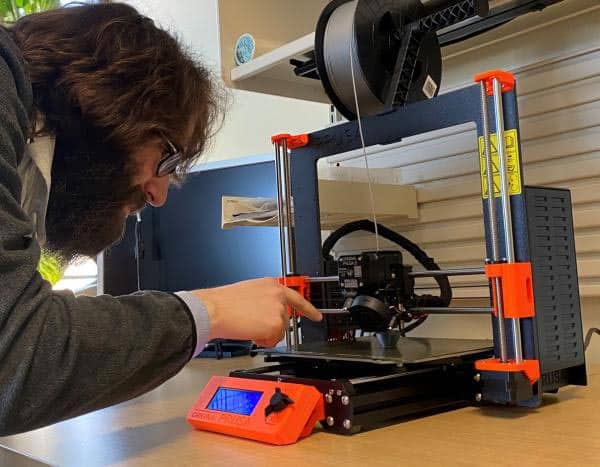

As an integral communication tool, our 3D printer transforms design concepts into scaled physical prototypes for absolute understanding of the end product. Initially incorporated to ascertain its capabilities and level of usefulness, the 3D printer has quickly proven effective for visualization purposes on projects in each of our office’s disciplines.

The printer works by pushing melted plastic through a motorized nozzle that moves in different directions to layer the deposited plastic in a shaping formation. The material cools and hardens while the layers gradually build up to create a three-dimensional shape. This can sometimes be a lengthy process depending on the size and intricacy of the component being printed. The heating element and extrusion of plastic works very similar to a hot glue gun but at more of a micro-scale.

Earlier in the year, this remarkable little gadget was successfully incorporated on multiple occasions. It assists with both site and structural projects and is incredibly effective portraying elements such as stairways, ramps, and walls.

The most notable advantage to our 3D printing is that the physical models greatly simplify discussions. Rather than flipping through large sets of drawings or quickly sketching what something may look like in perspective, we can simply point to the parts of the models, pass them around, and rotate them freely to convey design intent or review potential obstacles.

Our assistant designer Alan Greer enjoys a direct benefit that relates specifically to the use of time.

“While I still have to create a model in a 3D modeling software for the printer to work from, the actual printing process is completely hands off,” he said. “While the prints might be time consuming, I can be working on other tasks while it’s operating.”

We look forward to what the future will bring us with this advanced technology.

This stairway was created as one of many 3D projects.

Alan Greer works on a project using a 3D printer.